The company

Our history

Cam Hospital s.r.l is a medical device production company founded in 1986.

It is present in the medical sector with the firm desire to progress and offer considerable support in the evolution of hospital techniques through studies and designs of disposable technical devices.

Over the years, it has launched new production lines for medical devices aimed at satisfying the most varied needs in the field of surgical procedures, also offering the opportunity to customize the devices, with the primary objective of creating increasingly higher quality products.

The company’s quality procedures and increasingly advanced manufacturing systems represent the guarantee of reliability recognized today nationally and also in Europe.

It has obtained CE marking from ISS since 1998 and UNI EN ISO 9001:2008 certification from TUV. The 3,200 m2 production plant. it is made with modern technological systems, designed for the production of medical devices, equipped with “CLEAN ROOM” created according to the dictates of the regulations that regulate contamination-controlled environments. The products are manufactured in compliance with Italian and European regulations that regulate production processes in general (ISO 13485) and specific for the production of healthcare items and medical devices (EN 46002). The plants, production systems and materials produced by Cam Hospital comply with what is expressly indicated by the new EU regulation no. 2017/745 on medical devices (Medical Device Regulation, “MDR”) which repealed the previous European directives on the subject and Legislative Decrees no. 507/92 and n. 46/97, introducing important changes to the regulation of the production and marketing of medical devices.

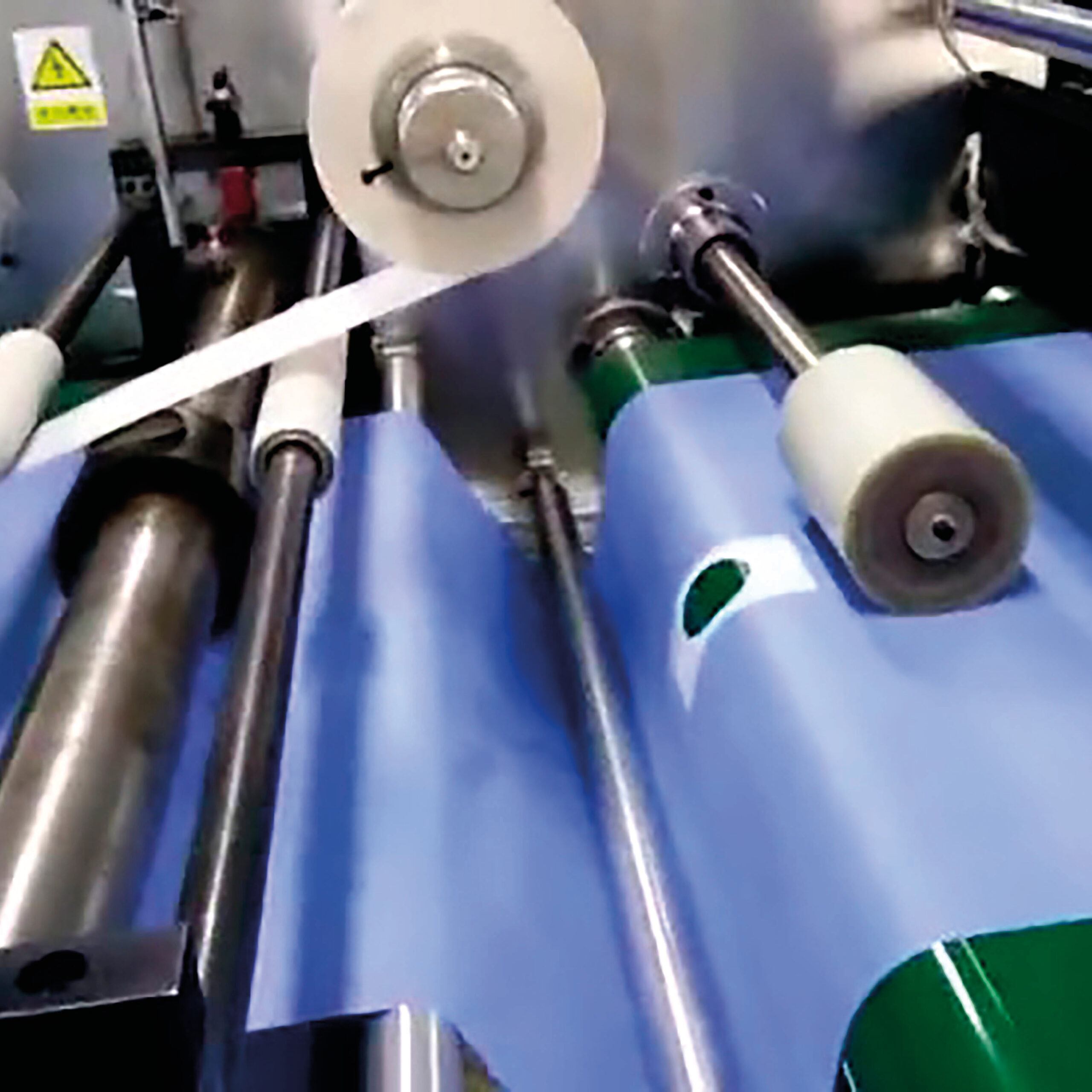

Production equipment

● Automatic machines for spreading, cutting and processing linen in general, gauze and dressings.

● Industrial sewing machines for the production of disposable healthcare clothing.

● Machines for molding plastic materials for the production of disposable instruments.

● Multi-purpose punching and riveting machines.

● Automatic machines for the in-line packaging of healthcare and specialist items.

Packaging methods

For the creation of the kits and the packaging of medical items in general, automatic packaging machines are used which obtain a blister from a polythene sheet where operators house the various devices in a clean room and which are automatically sealed with medical paper. All the necessary mandatory words and symbols are automatically printed on the package.

Research and technological innovation

UNI EN 13795 defined the European standards, establishing the essential requirements that operating room fabrics must satisfy, resulting from it a series of standards which are today the reference basis of CAM HOSPITAL for technological solutions that satisfy the safety, cost and and environmental impact. Considering the requirements dictated by the standard, the use of cotton in the operating room should be avoided, as the material is not safe for either the patient or the operator. Particular attention to respect and protection of the environment as well as the minimization of environmental impact are constantly guaranteed by the adoption of an Environmental Management System and the controlled management of production processes and activities relating to environmental protection (ISO 14001) .

Our mission

CAM HOSPITAL is a professional, innovative, reliable partner, capable of supporting the healthcare facility in its continuous growth towards excellence. Every need is analyzed and studied in partnership with the customer, configuring and customizing all surgical procedures

Our vision

Improve the quality and safety of surgical interventions performed in the NHS and consequently the quality of life of people through the implementation of an innovative approach to the management of the operating room thanks to the choice of an innovative, personalized, safe and eco-sustainable procedural kit.

The products shown in the catalogs are indicative and represent just some examples of our solutions and the know-how gained in over thirty years of experience. Contact us and tell us your specific needs; you will configure your product together with our specialists!

Contact us

follow us